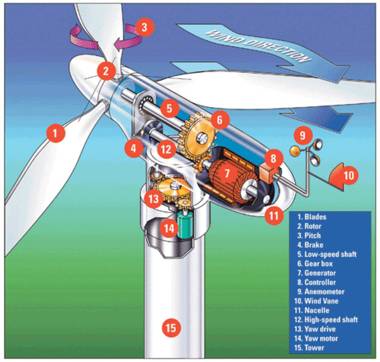

Pictured below is a cut away image showing the inside workings of a commercial wind turbine generator. Though large in size, such wind turbines are still very simple with relatively few components. Such simplicity is essential if the wind turbine is to be kept operational through years of extreme conditions.

Three turbine blades (1) make up the rotor. The pitch (3) of each blade can be changed (i.e. the blade can be rotated) to increase efficiency in low winds and to decrease efficiency (to protect the wind turbine) in very strong winds. In addition a brake (4) is fitted which can be set when dangerously strong winds are approaching or when the turbine is taken down for maintenance.

The rotor is spun by the wind causing the low-speed shaft (5) to rotate. This rotation is then passed onto the high-speed shaft (12) via a gearbox (6) which accelerates the speed of rotation to the levels necessary to generate high voltage electricity with the generator (7).

Everything is controlled via an electronic controller (8) which takes data inputs from an anemometer (9) which measures the speed of the wind, and a wind vane (10) which detects the direction of the wind. The nacelle (11) – the sealed unit at the top of the tower (15) – can then be automatically rotated to face into the wind with a yaw motor (14) turning the yaw drive (13).