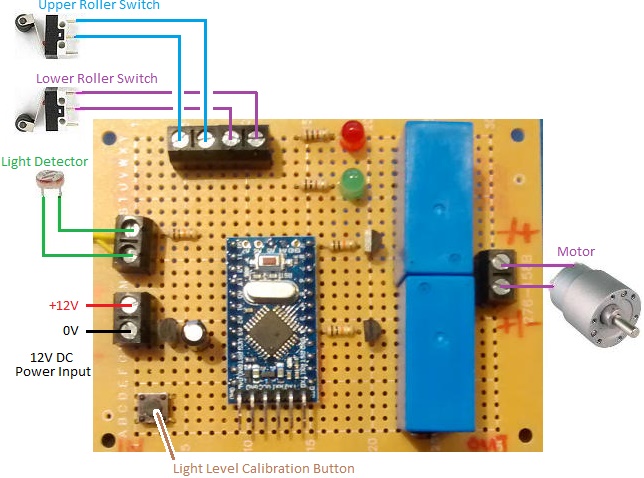

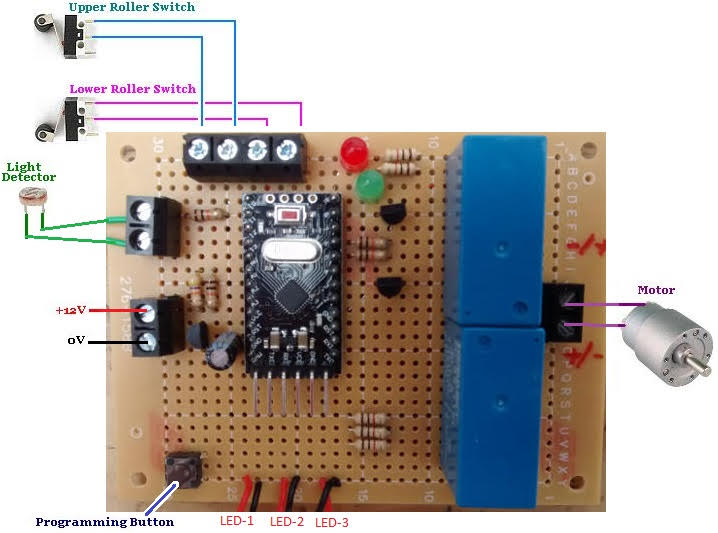

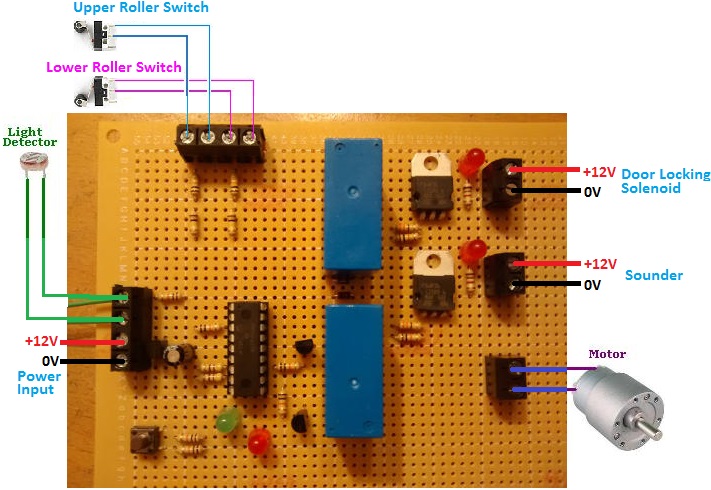

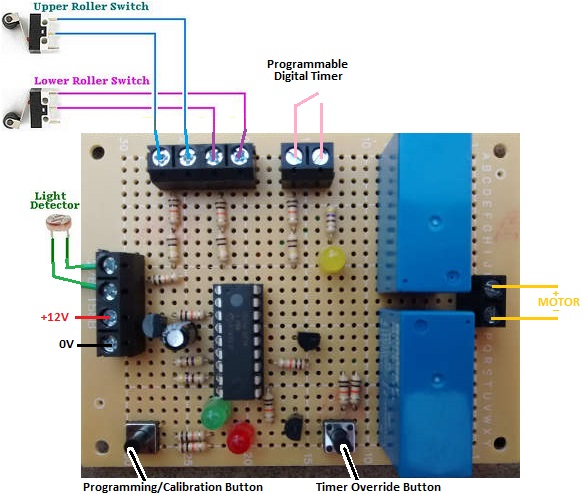

Pictured below is a new hen house door controller we recently made for a customer. Our most common design for a door opener/closer is our Dawn Dusk Henhouse Door Controller – a device which uses a couple of roller limit switches to keep track of the position of the door, and a light detector to detect dawn and dusk.

Our most common design for a door opener/closer is our Dawn Dusk Henhouse Door Controller – a device which uses a couple of roller limit switches to keep track of the position of the door, and a light detector to detect dawn and dusk.

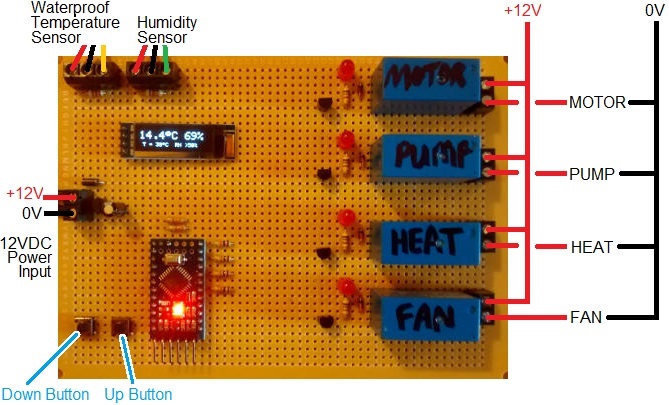

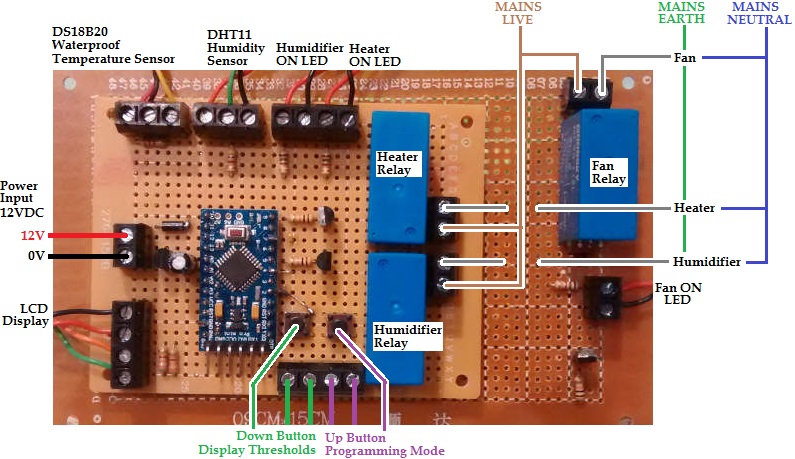

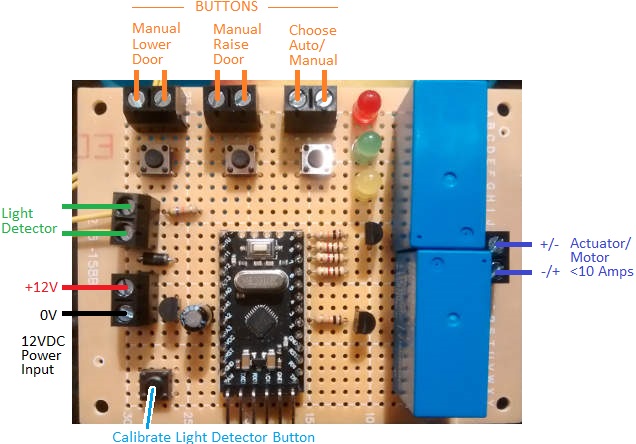

This new device is designed for operation with an aluminium screen door opened and closed by a linear actuator which has its own internal limit switches. At dawn, voltage is supplied to the actuator for one minute giving the actuator time to fully open the door with no worries that it will overrun thanks to the limit switches. At dusk, reverse polarity voltage is supplied to the actuator one one minute to close the door. The user can set the ambient light level threshold at which the door will open or close.

A further requirement for this controller was the ability to manually open or close the door at any time in order to give access to the chicken run. For this the user can select manual mode, and use the lower door or raise door buttons when they need to use the door. The controller keeps track of the position of the door during manual operation which is vital as there are no limit switches connected to the controller to tell it where the door is. On board buttons are available, but also screw in terminals so that external push-to-make buttons can be more conveniently located.

If you need any kind of door controller, please email neil@reuk.co.uk with details of your requirements.

Door Controller Instructions

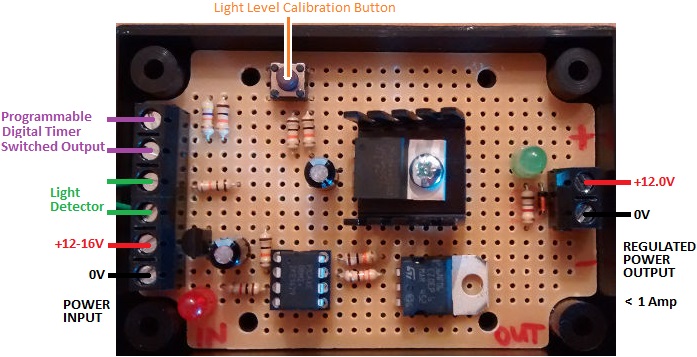

Light Detector

With the board connected up as per the diagram, the first step is to set the light detector threshold. The light detector is not waterproof, so it must be protected from rain, but also positioned so that it is exposed to natural light. The leads to the light detector can be extended to get it in an optimal safe location.

In the late afternoon / evening when the ambient light is at the level below which you want the door to be closed, press and hold the calibrate light detector button for more than one second. The red and green LEDs will then alternately flash for a few seconds and the current measured light level will be saved in memory as the night-dawn and day-dusk threshold.

Manual Operation

If the yellow LED is on, the device is in manual mode. To toggle between manual and automatic mode, press the choose auto/manual button.

In manual mode, pressing the manual lower door button will see power output to the actuator for one minute to close the door. (If during that one minute, you press the manual raise door button, power to the actuator will be cut leaving the door somewhere between open and closed.) Similarly, you can manually open the door by pressing the manual raise door button.

If you find that pressing the button to close the door instead opens the door, reverse the polarity of the power connections to the actuator.

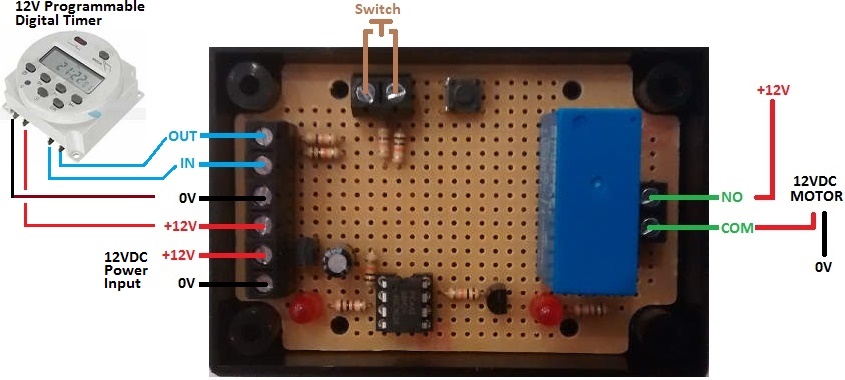

Automatic Operation

When initially powered on, the device assumes that it is day time and the door is open. (If you connect the power at midday with the door closed for example, the door will not open until the following morning unless you manually open it.)

When it gets ‘dark’ – light level measured to be below the user set threshold – the red LED will turn on. After 10 seconds of continuous ‘darkness’, the door will automatically be closed with power supplied to the actuator for one minute and the actuator’s internal limit switches preventing the door from overrunning. Now the device will sleep for two hours – red and green LEDs alternately flashing – so that no false dawns are detected if the skies suddenly brighten.

After the sleep, it will now be very dark. The device will wait through the night until dawn – light level measured to be above the user set threshold – and then turn on the green LED. After 10 seconds of continuous ‘light’, the door will automatically open, again followed by a 2 hour sleep to prevent the detection of a false dusk if clouds cover the sun.