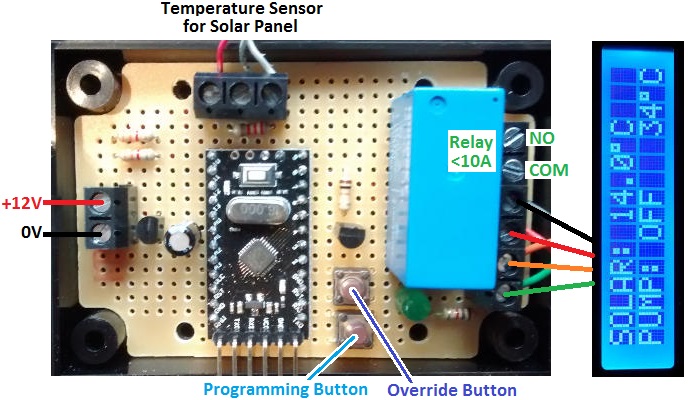

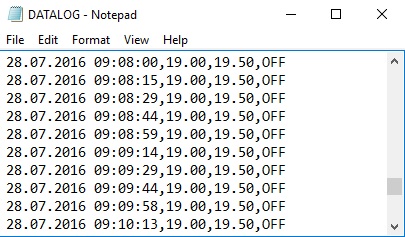

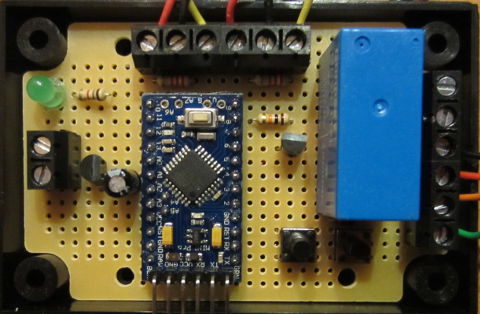

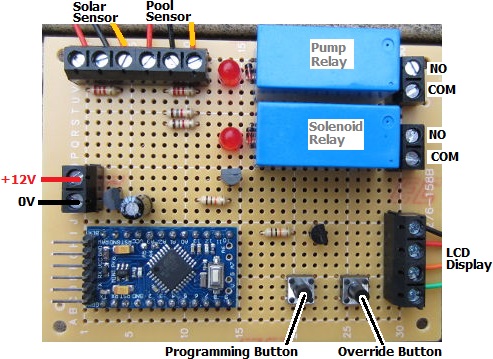

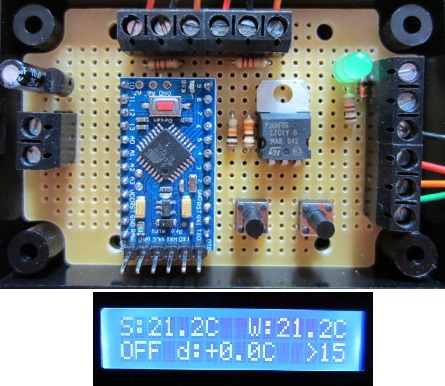

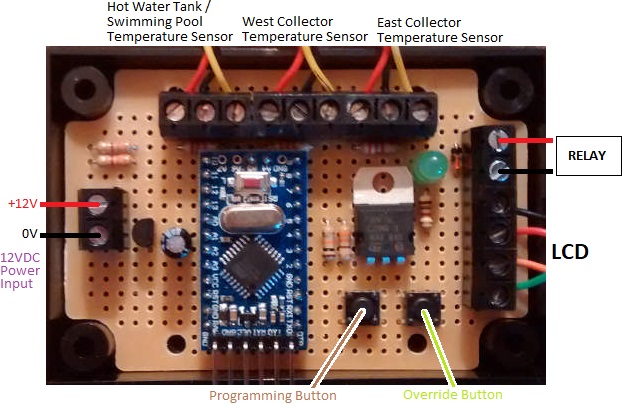

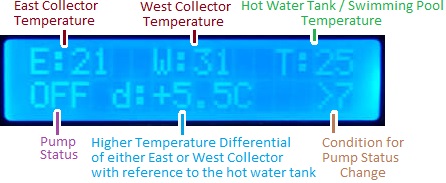

Pictured below is our standard 2016 Solar Water Heating Pump Controller with Datalogger. We recently made a modified version of this controller for use in a particular situation where the standard unit would not be very efficient.

In this case, the controller was to be used to heat a swimming pool. The problem was that this pool was located 30 metres away from a garage where the controller would be fitted, with 50mm water pipes already installed running underground to and from the pool from the garage (on the roof of which were installed solar water heating panels). There was therefore no easy way to retro fit a temperature sensor at the pool – that would necessitate digging a new 30 metre long trench, fitting sensor cable into an armoured tube, and burying it.

In this case, the controller was to be used to heat a swimming pool. The problem was that this pool was located 30 metres away from a garage where the controller would be fitted, with 50mm water pipes already installed running underground to and from the pool from the garage (on the roof of which were installed solar water heating panels). There was therefore no easy way to retro fit a temperature sensor at the pool – that would necessitate digging a new 30 metre long trench, fitting sensor cable into an armoured tube, and burying it.

It was however possible to fit a temperature sensor to the return water pipe where it emerged in the garage, but the contents of that pipe would cool down much faster than the large volume of water in the pool, and this would result in the pump being turned on frequently unnecessarily, often cooling the pool instead of heating it.

To get around this problem, the controller was modified to provide additional features. The key feature was that the pump would not be turned on until the temperature of the solar panel exceeded a user programmable value. When this threshold is reached, the pump is run for a user programmable number of seconds (TD) which circulates the water through the system sufficiently to get an accurate measurement of the temperature of the pool water. When TD seconds have elapsed, if the temperature differential between the solar panel and pool exceeds the user programmed differential (diffOFF), the pump will continue to run until the differential falls below diffOFF – standard operation for the 2016 controller.

If however after the test run of the pump, the differential is not high enough, the pump will be turned off, and the temperature of the pool sensor will be saved. For up to the next four hours this saved value of the pool temperature will be used rather than the sensor temperature (which will rapidly fall when the pump is turned off). The pool temperature over the course of 4 hours will not fall by more than a degree or two, so using this saved value is acceptable for efficiency. During the 4 hours, if the temperature differential exceeds the second user programmed differential (diffON), the pump will be run as per standard operation and after TD seconds the controller will start to use the current pool temperature sensor measurement instead of the previously saved value as the pipe in the garage will now be at pool temperature. The pump will continue to run until the differential falls below diffOFF.

If during the 4 hours, diffON is not achieved, the controller will wait until the solar panel temperature exceeds the user programmed temperature before running the pump for TD seconds again and repeating the above processes.

Overall these modifications (together with a few additional features not described above) will result in a far more efficient system than our standard controller would have given and less wear on the pump.

If you have any special requirements which are not met by our standard controllers, please email neil@reuk.co.uk with details.

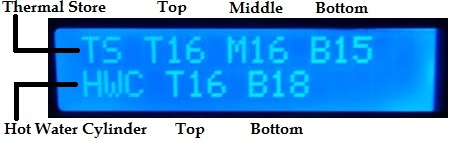

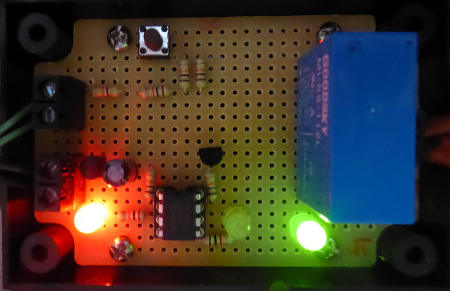

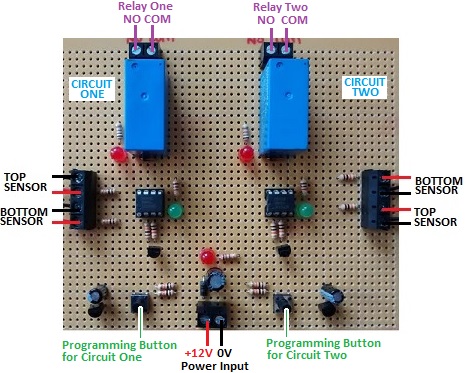

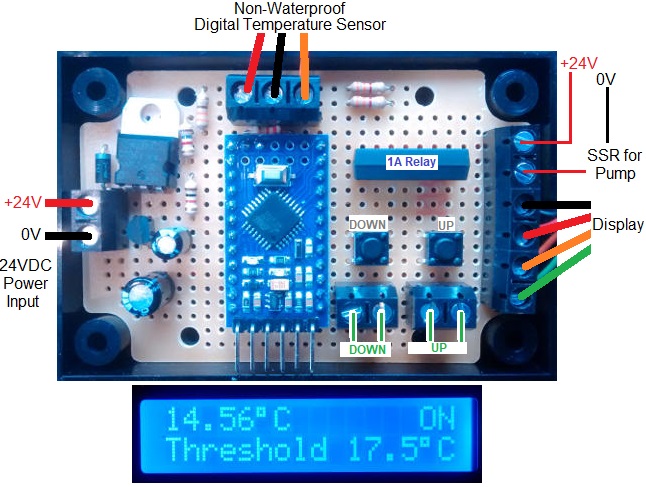

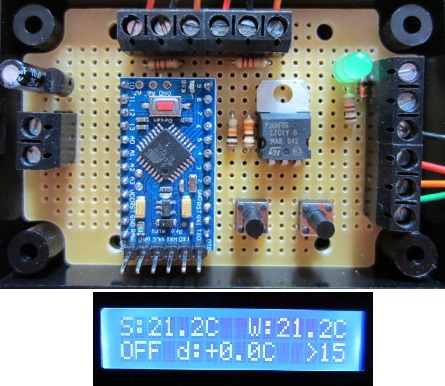

Pictured above is the device we came up with. The user can set a target temperature threshold of 15 and 30 °C in 0.5°C steps using the UP and DOWN buttons. If the temperature of the water falls to 0.25°C or more below the threshold, then a relay closes which turns on a heater. When the temperature of the water has reached 0.25°C or more above the threshold, the relay opens again and the heater turns off. This keeps the water within +/- 0.25°C of the target temperature.

Pictured above is the device we came up with. The user can set a target temperature threshold of 15 and 30 °C in 0.5°C steps using the UP and DOWN buttons. If the temperature of the water falls to 0.25°C or more below the threshold, then a relay closes which turns on a heater. When the temperature of the water has reached 0.25°C or more above the threshold, the relay opens again and the heater turns off. This keeps the water within +/- 0.25°C of the target temperature.

In this case, the controller was to be used to heat a swimming pool. The problem was that this pool was located 30 metres away from a garage where the controller would be fitted, with 50mm water pipes already installed running underground to and from the pool from the garage (on the roof of which were installed solar water heating panels). There was therefore no easy way to retro fit a temperature sensor at the pool – that would necessitate digging a new 30 metre long trench, fitting sensor cable into an armoured tube, and burying it.

In this case, the controller was to be used to heat a swimming pool. The problem was that this pool was located 30 metres away from a garage where the controller would be fitted, with 50mm water pipes already installed running underground to and from the pool from the garage (on the roof of which were installed solar water heating panels). There was therefore no easy way to retro fit a temperature sensor at the pool – that would necessitate digging a new 30 metre long trench, fitting sensor cable into an armoured tube, and burying it.