Wind Turbines are designed to rotate to face the wind and extract the maximum possible amount of power from it. With the wind often changing direction frequently this can lead to the that emerge from the wind turbine generator becoming twisted. Usually they will untwist themselves during periods of no wind, but if left tangled wires can be damaged and connections lost with potentially disastrous consequences. A Slip Ring is one elegant solution to that problem.

What is a Slip Ring

One definition of a slip ring is An electromagnetic device allowing the transmission of power from a stationary to a rotating structure. One side is kept stationary – in this case connected to the wires which go to battery storage, to a inverter, and/or to a bridge rectifier, while the other side can rotate freely into which the wires from the wind turbine generator are connected. As the wind turbine generator rotates on top of its pole, none of the rotation is transmitted through the cables below the slip ring.

Many different types of slip ring are available, the majority for use in domestic fans and similar products – however, these are not suitable for use with wind turbine generators as they cannot carry enough current.

Slip Rings for Wind Turbines

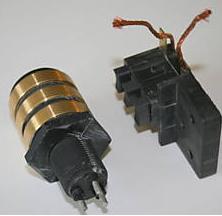

A slip ring is mounted on an insulated shaft with the electical connections from the wind turbine made to a conductive ring which is free to rotate. Brushes (contacts) are fixed in place (to which the batteries etc are connected) and remain in constant contact with the ring rubbing against it as it rotates. This over time leads to the brushes wearing down or becoming clogged with debris. Therefore it is essential that a low maintenance high quality slip ring is chosen. In order to reduce friction roller bearings are used within the slip ring assembly.

The slip ring pictured above offers three electrical connections and so can be used with three wires – ideal for the three phase AC typically output from most wind turbines where the alternator is at the top of the mast, and rectification (conversion to DC for battery charging) occurs at the bottom of the mast. If a DC generator is used, then just two of the three connections can be used. This particular unit can carry up to 65 Amps continuously and is sold here: wind turbine slip ring for around £20.

Alternatives to Slip Rings

An alternative to a wind turbine split ring is a simple plug connector positioned at the bottom of the wind turbine mast.When the wires become excessively twisted it can be unplugged, untwisted and re-plugged in. However this can only be done when the wind turbine is not turning or in a sudden gust of wind it could speed up excessively and be damaged. Welding cable should be used since it is highly flexible and designed to carry high currents.