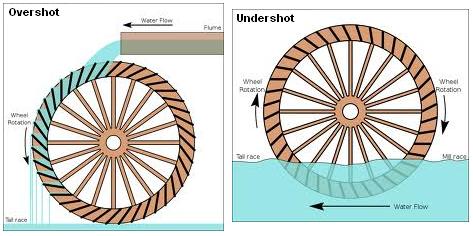

In our article Introduction to Water Wheels we introduced Undershot and Overshot water wheels together with other alternatives.

Each different type of water wheel has its advantages and disadvantages as well as features which make them suitable or unsuitable for different situations. In this article we will present a detailed mathematical analysis looking at the maximum possible efficiency of the overshot and undershot designs of water wheel. Many thanks to retired radio physics lecturer Bill for sharing this work with us.

Derivation of Water Wheel Efficiencies – Overshot vs Undershot

ABSTRACT

The efficiencies of various types of water wheel are often quoted but it can be difficult to find a derivation. Only two types are discussed the overshot and the undershot. It is almost common sense to recognise that a greater efficiency will be realised when the wheel is overshot because we are using the weight of the water as well as the kinetic energy inherent in the water by virtue of its flow.

INTRODUCTION

Water wheels have been with us some time and because of the spiralling cost of hydrocarbon fuels more people with the appropriate land and water are turning back to the water wheel for a cheap supply of power for heating and lighting.

This document looks albeit very superficially at water wheels and their efficiencies. There are a large number of variations of water wheels each with their own advantages and disadvantages. I have avoided the Pelton wheel which is far superior to a conventional water wheel – one of the reasons for this is because it extracts nearly all of the available energy by virtue of the reversal of momentum due to the shape of its cups.

Click here to download the full Derivation of Efficiencies (PDF 120Kb).