A low voltage battery disconnect (LVD) is a circuit which will automatically turn off the load connected to a battery if the battery voltage falls to low. Preventing lead acid batteries from being deeply discharged is absolutely key in terms of ensuring battery longevity.

We sell a selection of user programmable low voltage disconnect circuits for 12V battery systems. Set the voltage at which the battery is to be disconnected, and the voltage at which the low voltage disconnect is to be cancelled with ease. Click here to find out more and/or to buy REUK Programmable Low Voltage Disconnect (LVD) with relay, here for a mini 12V programmable LVD, or here for our newmini 24V programmable LVD.

We also sell a range of low voltage disconnect circuits with LCD displays and/or dataloggingfunctionality – contact us for details.

Low Voltage Disconnect

Putting together a low voltage disconnect circuit is not as simple as it may initially appear. If you were to simply use a relay to disconnect the battery from the load whenever the battery voltage falls below 11.5V say, then immediately after the load is shut off, the battery voltage will jump up again re-connecting the battery to the load! These on/off oscillations (multi-switching) are the last thing you want to happen, so hysteresis must be introduced to the circuit.

LVDs and Hysteresis

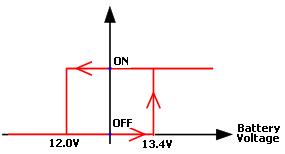

Hysteresis is defined as The dependence of the state of a system on the history of its state. For us in this application, it means that if we disconnect the load from the battery when its voltage is X, we only re-connect it if the battery voltage has increased to X + y (where y is greater than the jump in the battery voltage when the load disconnects). For 12V lead acid batteries we have found that the value of y should be at least 0.5V, and ideally 1.0V for greater system stability.

Good quality power inverters are always fitted with LVD capability – typically turning off the inverter when battery voltage falls to 11.5V and back on when it reaches 12.5-12.7V. Similiarly, solar charge controllers are also fitted with LVD again with cut off at around 11.5V and reconnection at 12.5+V.

If a battery is already being pulled down to 11.5V, it must be under a very heavy load, or be well discharged. Therefore, for our solar systems we typically suggest a 12.0V cut off, and a 13.4V reconnection voltage. The higher than standard reconnection voltage means that the load will only be re-connected to the battery when the solar panel is generating well and recharging the battery.

LVDs and Time Delays

In addition to taking care of hysteresis, a good low voltage battery disconnect will also include a timer. When a pump or motor is first switched on for example, the battery voltage will dip down (due to the high current required to start the pump/motor from stationary) for less than a second. We do not want the LVD to trigger during that time, so a good solution is to only trigger the LVD if the battery voltage has been constantly below the cut-off threshold for 10 seconds. Similarly, we don’t want the LVD to reconnect the load if there is a sudden spike in battery voltage, so re-connection of the load should only take place when the battery voltage has been above the turn-on threshold for 10 seconds.

Other Useful LVD Features

An LVD can be made to sound an audible alarm or flash a warning light when the cut-off threhold is reached without necessarily disconnecting the load at the same time. The user will then know he must recharge the battery without anything being automatically switched off – a useful feature for example on a boat where you would not want the lights, GPS and other crucial electronics being turned off. Similarly, an early warning alarm could be sounded at battery voltages below 12.0V with the automatic cut-off only being triggered when the battery voltage reaches a truly critical level – e.g. 10.5V (often a feature found on higher quality power inverters).

A manual override/reset is a useful feature to reset the hysteresis if required, and LED indicators can be used to show the current system status and battery voltage.

Putting Together an LVD Circuit

For the low voltage battery disconnect circuits we put together, we use PICAXE, or Arduinomicrocontrollers. We pass the battery voltage through a voltage divider and input it to the microcontroller chip. We programme the microcontroller to implement the required LVD features outputting a signal via a transistor to the coil of a suitably rated relay (automotive relays whenever greater than 10 Amps of current is to be switched.)

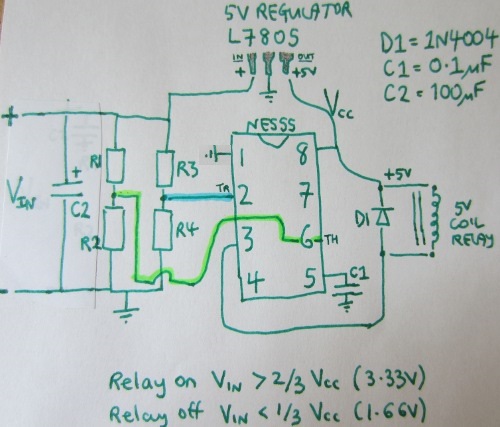

In our article Simple Low Voltage Disconnect with NE555 we show how the simple and inexpensive bare-bones low voltage disconnect circuit pictured above can be made using just an NE555 timer IC chip and some other readily available components.

Buy a Low Voltage Battery Disconnect Circuit

If you need a bespoke LVD circuit made for any application, please contact neil@reuk.co.uk with details of your exact requirements and we should be able to put something together for you.