Many of the products we sell make use of 16×2 character LCD displays. These displays coupled with an Hitachi HD44780 LCD control module enable an Arduino or Raspberry Pi to operate the display very simply with just two data connections and two power connections required.

However, these displays are physically quite large being 80 x 36mm, and while they are well suited to panel mounting, they cannot really be attached to the circuit board that is driving it without creating a device with large dimensions.

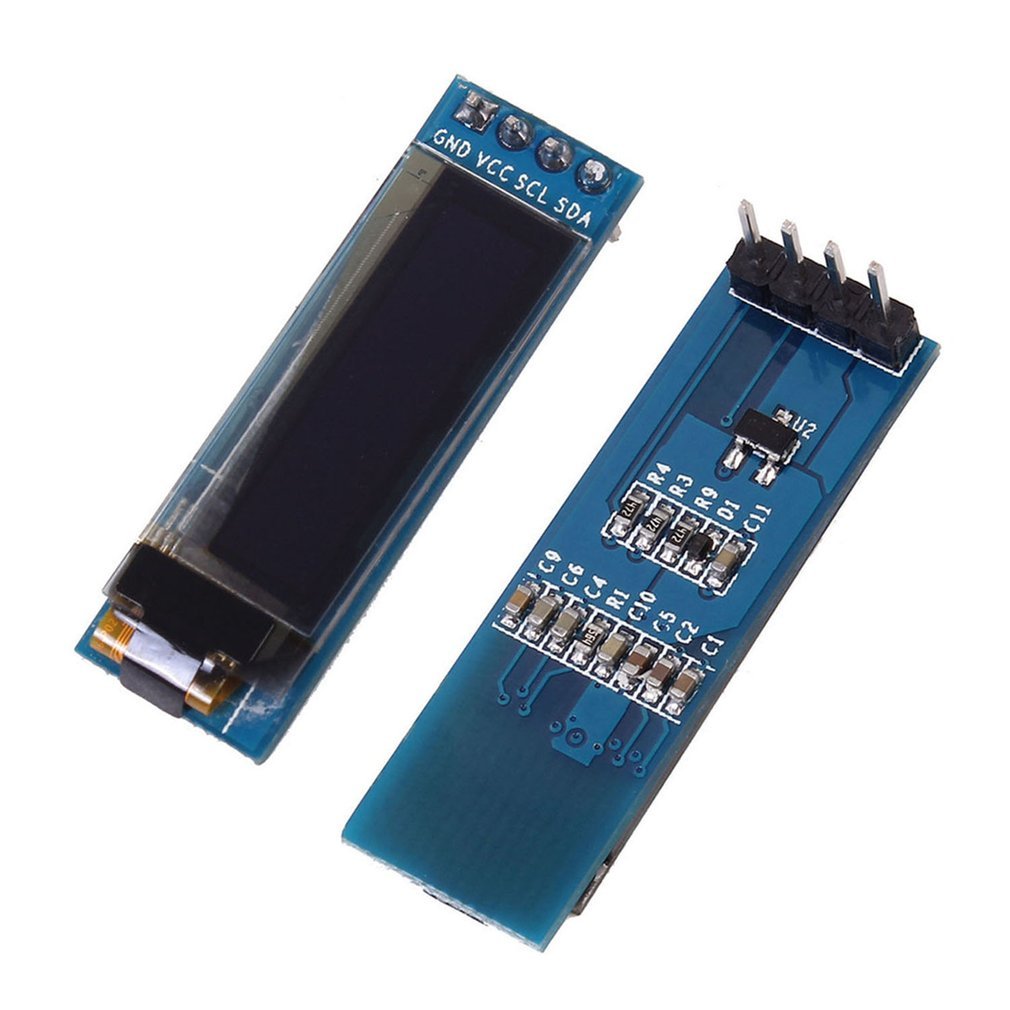

We have recently being looking at alternatives to these displays looking for something physically smaller, easily circuit board mountable, lower power consumption, and improved contrast. After much testing, we have chosen the OLED display pictured below. These displays are far smaller having an active screen area of just 22.38 x 5.58mm. They require no backlight as each of the 128×32 pixels self-illuminates thanks to OLED technology. The maximum power consumption of one of these displays is 0.08W with every pixel illuminated – therefore less when showing text or when nothing is being displayed. In all ways these displays are an improvement on the 16×2 character LCDs.

These displays are far smaller having an active screen area of just 22.38 x 5.58mm. They require no backlight as each of the 128×32 pixels self-illuminates thanks to OLED technology. The maximum power consumption of one of these displays is 0.08W with every pixel illuminated – therefore less when showing text or when nothing is being displayed. In all ways these displays are an improvement on the 16×2 character LCDs.

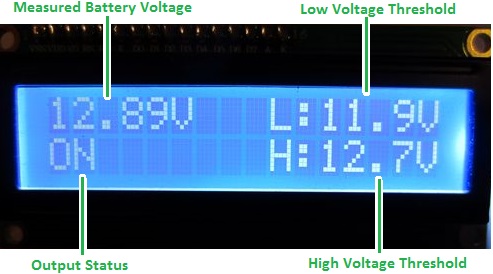

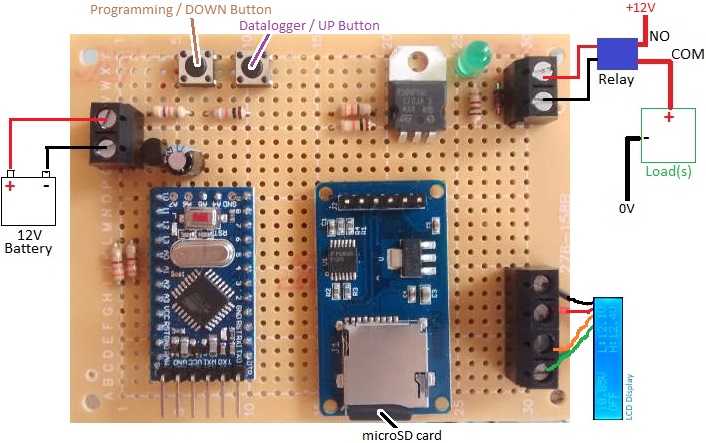

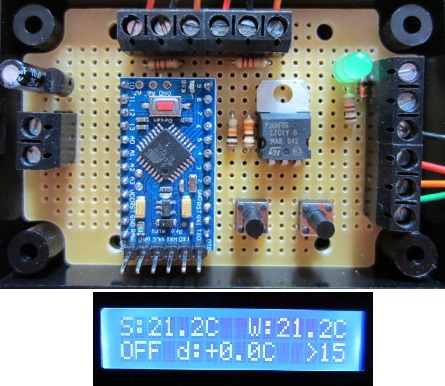

These OLED displays have much better contrast than LCDs, there is more space available to display information since more characters can be displayed, and there are much better graphics capabilities with the OLED displays. The image above shows the new OLED version of the LCD display from our REUK Low Voltage Disconnect with Display pictured below.

These OLED displays have much better contrast than LCDs, there is more space available to display information since more characters can be displayed, and there are much better graphics capabilities with the OLED displays. The image above shows the new OLED version of the LCD display from our REUK Low Voltage Disconnect with Display pictured below.

The biggest advantage however is the ease with which these OLED displays can be mounted to the circuit boards of our controllers so that we can produce more convenient small form factor integrated units with no increase in our pricing for customers.

If you are interested in trying out one of these displays for your own projects, click here: buy 128×32 OLED Display for under £3 including delivery. If you intend to use one with an Arduino project, you will need to add the following libraries to your Arduino IDE: SSD1306 Library and Adafruit GFX Library, so that you can communicate with the display.

In this case, the controller was to be used to heat a swimming pool. The problem was that this pool was located 30 metres away from a garage where the controller would be fitted, with 50mm water pipes already installed running underground to and from the pool from the garage (on the roof of which were installed solar water heating panels). There was therefore no easy way to retro fit a temperature sensor at the pool – that would necessitate digging a new 30 metre long trench, fitting sensor cable into an armoured tube, and burying it.

In this case, the controller was to be used to heat a swimming pool. The problem was that this pool was located 30 metres away from a garage where the controller would be fitted, with 50mm water pipes already installed running underground to and from the pool from the garage (on the roof of which were installed solar water heating panels). There was therefore no easy way to retro fit a temperature sensor at the pool – that would necessitate digging a new 30 metre long trench, fitting sensor cable into an armoured tube, and burying it.